Fabrication of Base Fabric

There are three main types of tension fabric used in architectural applications today: PVC coated polyester, silicon coated fiberglass, and Teflon coated fiberglass. PVC coated polyester is the cheapest and easiest to manage of the three but also has the shortest life span. Teflon and silicon coated fiberglass are more durable, but are also more expensive. However, the basic structure of the material is similar for all three. The bottom layer of the tension fabric is a base fabric, usually made out of polyester or fiberglass. This fabric is created with fibers that run perpendicular, or in the warp and welt directions, and are weaved in and out of each other. The base fabric is extremely important as it dictates a number of the final fabric properties including stress and strain properties (how much force the fabric can take and how long it can stretch before failure). The end result is an incredibly strong material: fiberglass fiber has a tensile strength of 3200 Mega-Pascal (MPa). To put this number in perspective, structural steel only has a tensile strength of roughly 250 MPa. In order to create a stronger final fabric, one could use a bigger denier (size) of fiber or create a fabric with more fibers per square inch. In addition to the incredible strength of the base fabrics, they are also relatively translucent and reflective. For example, Teflon coated fiberglass has a reflectivity of seventy percent.

The Exterior Coating

Once the base fabric has been created all that is left to do is coat the fabric with an exterior coating. Generally, the exterior coating appears at the beginning of the name of a tension fabric: for example, Teflon coated fiberglass is coated with Teflon or Poly Tetra Fluoro Ethylene (PTFE). Teflon and silicon are durable coatings that guard against ultraviolet radiation, moisture, and microorganism infestation. They are 'self cleaning', meaning that dust, dirt, ash, and chemical pollutants all wash off in the presence of water. The main difference between the two is that while Teflon is a better self cleaner, it is also more expensive to produce. PVC coating has many of the same properties as Teflon and silicon. However, it is susceptible to UV radiation and, consequently, has a shorter life span.

Important Application Criteria

But how is a fabric able to hold the wind, snow, and gravity loads associated with roofs? If the roof is only made out of fabric, why does the fabric not sink when weight is applied? The answer lies in the pre-stressing of the tension fabric and the final shape in which the tension fabric is placed.

Essential Pre-stressing

Pre-stressing refers to the process by which the fabric is loaded upon construction. To find the amount of pre-stressing necessary, the engineer must calculate the expected loads for the duration of the structure. The pre-stressing should account for the maximum possible load in both the X and Y directions throughout the course of the fabric. This amount of pre-stressing is very important. If the pre-stressing is too high, unnecessary building materials will be needed to counteract the large tension force created by the fabric. If it is too low, the structure will be vulnerable to vibrations caused by wind (Intents).

Form follows Function

While a two dimensional tension fabric membrane can take planar tensile forces, it can not take significant forces perpendicular to this plane. Therefore, in addition to being pre-stressed, tension fabric must take a certain three dimensional shape in order to remain stable. These shapes were discovered by Otto and Berger during their investigation of natural forms such as soap bubbles. There are two types of general shapes: anticlastic and synclastic shapes.

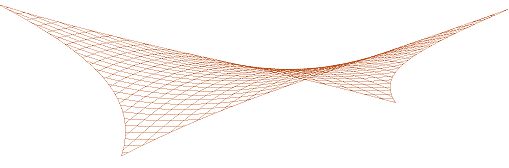

Anticlastic shapes are created by having the radii of the principal curvatures on opposite sides of the tension fabric surface. As a result, when loaded at a particular point, tension will increase on one curve of the membrane and leave the opposite curve, thereby preserving equilibrium and keeping the structure stable. In order to keep anticlastic shapes, some kind of structural frame or support is necessary in the form of cables or steel beams. Some examples of anticlastic shapes are saddle, cone, and wave forms (Fig. 1)

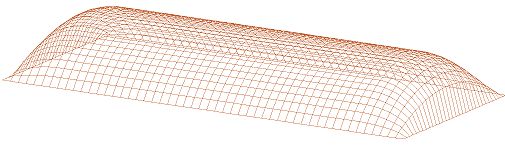

On the other hand, synclastic shapes are characterized by having the radii of the principal curvatures on the same side of the fabric (Fig. 2). In order to counteract external forces, pressure from within is necessary. This is why synclastic shapes are associated with air inflated structures, as the difference of pressure created by air pumped into the building is able to counteract external forces in the form of wind or snow.